BERZELIUS Stolberg GmbH

GLOBALLY LEADING PRIMARY LEAD SMELTER WITH WORLD CLASS QSL TECHNOLOGY

With a workforce of almost 275, the BERZELIUS Stolberg (BBH) is one of the largest and most modern lead smelters in the world.

Founded in 1848, this primary smelter attained market leading status in 1990 when it introduced the world leading QSL process, which to this day remains at the forefront of technology in lead production. Another major investments and successful projects with underline the status of the World class production site, using the second largest software process control system in German to run the plant.

In addition to lead and lead alloys, BBH also produces sulphuric acid and silver, copper/lead matte and BERZELIT® slag. The silver is doré silver ("Güldischsilber"), won by the separation of precious metals consisting of 99.6% silver, gold and platinum from lead concentrates which again sets international standards in terms of quality.

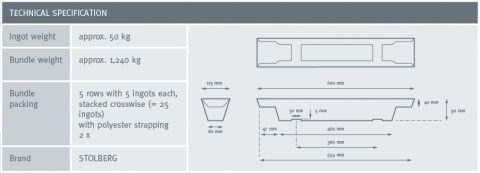

The plant produces 155,000 tonnes of lead and more than 100 different specifications of lead alloys, which are recognised as market leading products. The market-listed high-purity lead has certified elements with an accuracy of 1ppm and is produced under the brand name STOLBERG.

In 2014, BBH erected a new silver plant and is now in the position to produce 700 tonnes of this precious metal.

FACTS AND FIGURES

- approx. 275 employees

Production facilities:

- Primary lead smelter with QSL technology

- Sulphuric Acid plant

- Silver plant

Annual production (approx.):

- 155,000 tonnes lead/lead alloys

- 130,000 tonnes sulphuric acid

- 60,000 tonnes BERZELIT®

- 6,000 tonnes copper/lead matte

- 700 tonnes silver

- 1,200 kilos gold

------------------------------------------------------------------------

Documents

-

Datenschutzhinweise BBH

(274 KB)

Datenschutzhinweise BBH

(274 KB)

-

Company Brochure BBH

(714 KB)

Company Brochure BBH

(714 KB)

-

Broschüre BBH

(723 KB)

Broschüre BBH

(723 KB)

-

Auftragsbedingungen BBH

(32 KB)

Auftragsbedingungen BBH

(32 KB)

Certificates

-

BBH_50001_EN.pdf

(377 KB)

BBH_50001_EN.pdf

(377 KB)

-

BBH_50001_DE.pdf

(380 KB)

BBH_50001_DE.pdf

(380 KB)

-

BBH-OHSAS-18001-EN.pdf

(138 KB)

BBH-OHSAS-18001-EN.pdf

(138 KB)

-

BBH-OHSAS-18001-DE.pdf

(135 KB)

BBH-OHSAS-18001-DE.pdf

(135 KB)

-

BBH-ISO14001-EN.pdf

(137 KB)

BBH-ISO14001-EN.pdf

(137 KB)

-

BBH-ISO14001-DE.pdf

(162 KB)

BBH-ISO14001-DE.pdf

(162 KB)

-

BBH-ISO9001-EN.pdf

(138 KB)

BBH-ISO9001-EN.pdf

(138 KB)

-

BBH-ISO9001-DE.pdf

(164 KB)

BBH-ISO9001-DE.pdf

(164 KB)

-

BBH-EFB-DE.pdf

(502 KB)

BBH-EFB-DE.pdf

(502 KB)

Contact

BERZELIUS Stolberg GmbH

Binsfeldhammer 14

52224 Stolberg, Germany

Phone +49 2402 1206-100

Fax +49 2402 1206-209

bbh@berzelius.de