Muldenhütten Recycling und Umwelttechnik GmbH

SECONDARY LEAD SMELTER WITH INTEGRATED INCINERATION FACILITY FOR HAZARDOUS WASTES

Muldenhütten Recycling und Umwelttechnik GmbH (MRU) is the third largest lead smelter in Germany. The smelter, founded in the 14th century, was converted to a smelter for secondary materials in 1969, and then modernised between 1993 and 1994 to conform to most modern Standards. MRU is continuously expanding and improving its facility to maintain the highest possible operational standards. Today, MRU employs 155 staff to process around 55,000 tonnes of lead and lead alloys, including tin and antimony master alloys.

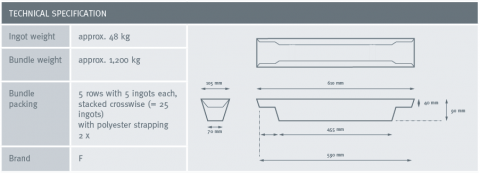

Since 2012, MRU is the second Polypropylene reground producer in the ECOBAT group with an annual quantity of 15,000 tonnes. The Polypropylene, obtained as a by-product of the pre-treatment process, is refined to Polypropylene compounds - a material much in demand by the international automotive industry for manufacturing external plastic linings for their newer car models. The product, marketed under the trade name Seculene® PP, is highly regarded in this market.

The plant also produces sodium sulphate. MRU is unique among the lead smelters worldwide, in that it has its own integrated incinerator for hazardous wastes. This enables the recovery of hazardous non-recyclable plastic wastes, which are produced during the pre-treatment of accumulators.

FACTS AND FIGURES

- approx. 155 employees

Production facilities:

- Secondary lead smelter with integrated incinerator for hazardous wastes

- Polypropylene Extrusion plant

Annual production (approx.):

- 55,000 tonnes lead and lead alloys

- 15,000 tonnes Seculene,

- 5,000 tonnes sodium sulphate

- 1,000 tonnes antimony and tin master alloys

-

18,000 tonnes hazardous wastes in the incinerator plant

------------------------------------------------------------------------

Documents

-

PP-Broschüre deutsch ECOBAT

(7404 KB)

PP-Broschüre deutsch ECOBAT

(7404 KB)

-

PP-Brochure english ECOBAT

(7404 KB)

PP-Brochure english ECOBAT

(7404 KB)

-

Datenschutzhinweise

(1950 KB)

Datenschutzhinweise

(1950 KB)

-

Company Brochure MRU LEAD

(753 KB)

Company Brochure MRU LEAD

(753 KB)

-

Company Brochure MRU COMBUSTION

(677 KB)

Company Brochure MRU COMBUSTION

(677 KB)

-

Broschüre MRU Verbrennung

(677 KB)

Broschüre MRU Verbrennung

(677 KB)

-

Broschüre MRU Blei

(751 KB)

Broschüre MRU Blei

(751 KB)

Certificates

-

MRU EfbV DE

(956 KB)

MRU EfbV DE

(956 KB)

-

MRU OHRIS EN

(308 KB)

MRU OHRIS EN

(308 KB)

-

MRU OHRIS DE

(318 KB)

MRU OHRIS DE

(318 KB)

-

MRU ISO50001 EN

(194 KB)

MRU ISO50001 EN

(194 KB)

-

MRU ISO50001 DE

(194 KB)

MRU ISO50001 DE

(194 KB)

-

MRU ISO50001 EN

(175 KB)

MRU ISO50001 EN

(175 KB)

-

MRU ISO50001 DE

(175 KB)

MRU ISO50001 DE

(175 KB)

-

MRU ISO9001-14001 EN

(261 KB)

MRU ISO9001-14001 EN

(261 KB)

-

MRU ISO9001-14001 DE

(247 KB)

MRU ISO9001-14001 DE

(247 KB)

Contact

Muldenhütten Recycling und Umwelttechnik GmbH

Muldenhütten 25

09599 Freiberg, Germany

Phone +49 3731 367-0

Fax +49 3731 367-407

mru@berzelius.de